-

Semi-automatic winding machines

We wind spools of different shapes and sizes on our winding machines. We have multi-spindle winders that can wind multiple wires with precision. Some are of the "revolver" type, where the operator safely puts on and takes off one batch while the machine winds the other. We will manufacture the mandrels to your request in our tool room to meet all your requirements.

-

Robotic lines

We have a fully automatic robotic workstation, semi-automatic stations, a number of carousels and a lot of single-purpose machines.

-

Flat wire vertical winding

The machine for flat wire vertical winding is made by our own development department. This winding of the flat wire allows to achieve a large cooling surface of the winding and thus to optimize the dimensions of the finished product, especially in case of forced cooling. On our machinery, we can wind coils in rectangular layout with dimensions from 25 to 80mm or circular layout with an inner radius of 10mm.

-

Toroidal core production

For the production of cores we use oriented sheets with a thickness of 0.30mm and 0.27mm. We purchase material according to the standard ČSN EN 10107. We produce toroidal, oval and square cores. We are able to produce toroidal cores in the following dimensions: - outer core diameter da = 18 - 90 - inner core diameter di = 12 - 740mm - core height h = 5 - 100mm.

-

Laser cuting

We can cut sheets very quickly and accurately for you on a fully enclosed fibre laser with power from 6KW to 20KW on interchangeable 3000 mm x 1500 mm work surfaces. Carbon steels, stainless steels and non-ferrous alloys can be cut.

-

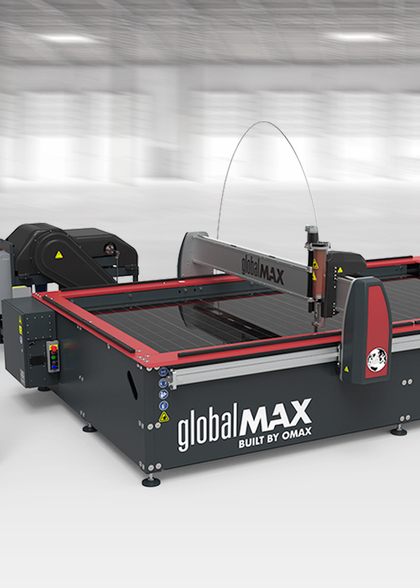

Water jet

The high power waterjet with a cutting area of 3050 mm x 1530 mm can cut parts with high clearance. The simple software converts drawings in common formats by itself. We can cut rubber, pertimax, glass, stone materials, PVC and foam, various metals and much more in thicknesses up to 1mm by 135mm.

-

Inject molding

On our injection moulding machine we are able to produce coils and other small parts from various types of plastic granulates. We can also put your product into plastic for better electrical, mechanical and IP protection.

-

Mechanical workshop

In our mechanical workshop we have CNC machines, milling machines, milling cutters, lathes and other professional equipment. Thanks to this we can produce any mechanical parts for your projects. We can process almost any material.

-

High capacity warehouse

We are equipped with a modern warehouse with a capacity of more than 4000 pallet places and 3000 boxes for materials and final products. The system automatically monitors batches, FIFO and everything is done via QR code and bar code scanning. There is also a warehouse with a cold room for storing temperature-sensitive materials.

-

Automatic hight resolution printers

We have many technologies for product identification and logo printing. One of them is IDTIJ, which enables fast stable printing at resolutions up to 750 DPI, which is heat and abrasion resistant and can be applied to almost any material. We use it mainly on plastics, metals and ceramics.

-

Research and Development

The Research and Development is engaged in the development of complex electronic devices, machines and special magnetic circuits. The development workplace is equipped with modern technologies and devices. We test the findings from the development in our own metrology laboratory. We have a large number of our own patents.

-

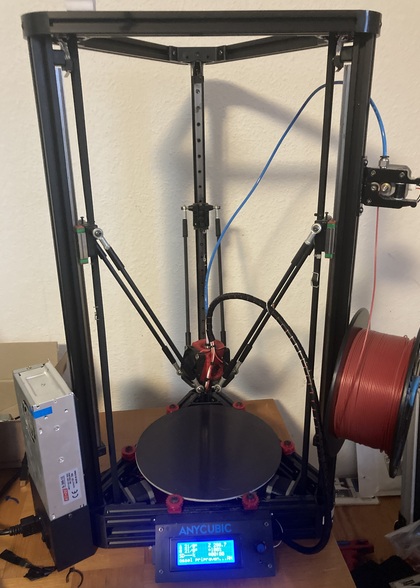

3D printers

We have FDM, SLA, MJF and SLM technologies for printing prototyp components for rapid decrease time of development of new products. We can print ,,bobbine,, for transformers, what is reason why we can produce samples without producing of mold. 3D print is also used for testing shape of thorns for winding new products.

Technologies

We use a wide range of modern technologies to manufacture our products, including robotic stations, winding machines, laser cutting, waterjet, 3D printing or injection moulding. These advanced processes ensure high quality and production efficiency, tailored to the needs of our customers. For more information about BV elektronik's production options, you can contact our specialists.

Do you have a question or want to submit an inquiry?

Contact form

Quick contact to the selected department